Potentially interested in working at zepp? click on this banner to stay up to date on new jobs and opportunities.

Als jij geïnteresseerd bent in ons, dan zijn wij waarschijnlijk ook geïnteresseerd in jou. Dus stel jezelf aan ons voor en laten we kijken of we een match voor elkaar zijn.

As a mechanical design engineer your responsibilities will lie in the fields of fuel cell, hydrogen storage or thermal management systems development. All three subsystems are of vital importance for a reliable and competitive zero emission operation. The core subsystems you will develop and test will be integrated into a vast variety of applications, ranging from maritime over automotive to aviation applications.

The fuel cell system is the heart of the operation. A compact design enables smart placement of the fuel cell in the application. High efficiency lowers consumption and increases range and endurance. High reliability is a must to be able to replace proven diesel technology. Production scalability through building block approach. As a design engineer for hydrogen fuel cell systems you have to combine a wide set of skills optimising a mechanical design consisting of several subsystems. You will be dealing with different media, temperatures, material specifications and other requirements. The subsystems of the fuel cell system deal with hydrogen, pure water, coolant, high and low voltage. Working on fuel cell modules includes the work of integrating existing components but also developing inhouse components and subsystems.

The largest and heaviest subsystem in most hydrogen applications is the hydrogen storage. The hydrogen storage reaches from the refuelling port on the vehicle, ship or generator via the tanks to the hydrogen interface on the fuel cell module. A large set of high pressure equipment needs integration along the way. At pressures of 350 to 700 bar safety and reliability are of utmost importance. Certification requirements in the different sectors ask for different design approaches in the different applications. The higher the hydrogen capacity, the longer the machine or truck can run before refuelling. The lighter the construction the higher the possible payload. Well performed structural design and analysis results in the largest performance gain when it comes to the hydrogen storage system.

Keeping all systems at their optimum working temperatures is key to enable smooth and reliable operation. Depending on the operation the thermal management subsystem can dictate the maximum power output of the fuel cell system, the more compact and efficient the design, the better the fuel cell performance also at high environmental temperatures. The design and working principle can differ from application to application. Where maritime applications can rely on liquid to liquid heat exchangers, trucks or stationary generators require large surfaces for gas (air) to liquid radiators, larger in size than their diesel counterpart. The thermal management system, an important building block of the hydrogen fuel cell powertrain, filled with challenges and room for novel developments.

You will facilitate your colleagues, the mechanical integration engineers, integrating your core subsystem into a customer specific zero emission solution.

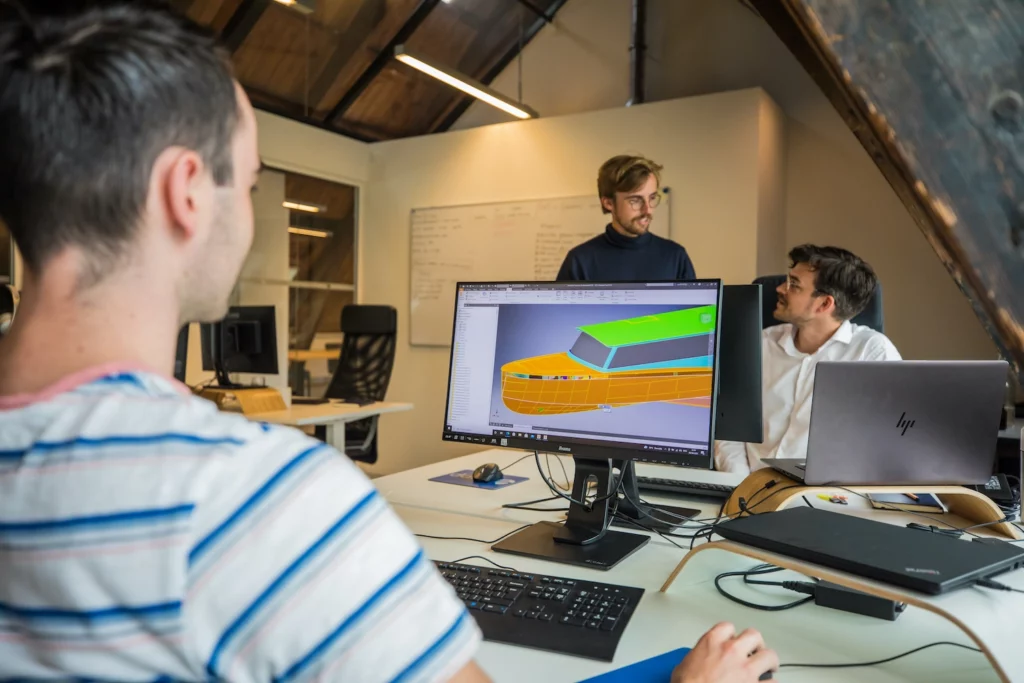

Designing mechanical components and systems in 3D-CAD, based on a large set of requirements is an important part of your job. You analyse them via FEA methods on their strength, mechanically stress test the components to verify the FEA and afterwards integrate new components and/or subsystems in the existing product, the fuel cell, thermal management or hydrogen storage system. You are responsible for the entire development cycle of your newly developed component/product. For new products/prototypes this also includes managing production and assembly.

Together with colleagues of other departments and specialisations you will perform system tests on the testbench and in the actual real life application in the field, being in a ship, truck or excavator.

We are looking for engineers who can easily adapt to the diversity of tasks that arises when working in a young and growing company. Team players who know how to mechanically design and integrate in a practical matter and understand the importance of durability.

You can apply to this vacancy using the button below. Please include a cover letter and CV.

For the selection procedure, we use an objective recruitment and selection method. After the letter-and-CV selection, there will be a round of interviews. If necessary, a second round of interviews will take place. Alternatively, an employment interview will be held.

| Cookie | Duur | Beschrijving |

|---|---|---|

| li_gc | 6 months | Linkedin set this cookie for storing visitor's consent regarding using cookies for non-essential purposes. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| player | 1 year | Vimeo uses this cookie to save the user's preferences when playing embedded videos from Vimeo. |

| sp_landing | 1 day | The sp_landing is set by Spotify to implement audio content from Spotify on the website and also registers information on user interaction related to the audio content. |

| sp_t | 1 year | The sp_t cookie is set by Spotify to implement audio content from Spotify on the website and also registers information on user interaction related to the audio content. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

| Cookie | Duur | Beschrijving |

|---|---|---|

| sync_active | never | This cookie is set by Vimeo and contains data on the visitor's video-content preferences, so that the website remembers parameters such as preferred volume or video quality. |

| Cookie | Duur | Beschrijving |

|---|---|---|

| __hstc | 6 months | Hubspot set this main cookie for tracking visitors. It contains the domain, initial timestamp (first visit), last timestamp (last visit), current timestamp (this visit), and session number (increments for each subsequent session). |

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| AnalyticsSyncHistory | 1 month | Linkedin set this cookie to store information about the time a sync took place with the lms_analytics cookie. |

| hubspotutk | 6 months | HubSpot sets this cookie to keep track of the visitors to the website. This cookie is passed to HubSpot on form submission and used when deduplicating contacts. |

| vuid | 1 year 1 month 4 days | Vimeo installs this cookie to collect tracking information by setting a unique ID to embed videos on the website. |

| Cookie | Duur | Beschrijving |

|---|---|---|

| __qca | never | The __qca cookie is associated with Quantcast. This anonymous data helps us to better understand users' needs and customize the website accordingly. |

| bcookie | 1 year | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser IDs. |

| bscookie | 1 year | LinkedIn sets this cookie to store performed actions on the website. |

| iutk | 6 months | Issuu sets this cookie to recognise the user's device and what Issuu documents have been read. |

| li_sugr | 3 months | LinkedIn sets this cookie to collect user behaviour data to optimise the website and make advertisements on the website more relevant. |

| mc | 1 year 1 month | Quantserve sets the mc cookie to track user behaviour on the website anonymously. |

| NID | 6 months | Google sets the cookie for advertising purposes; to limit the number of times the user sees an ad, to unwanted mute ads, and to measure the effectiveness of ads. |

| VISITOR_INFO1_LIVE | 6 months | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| VISITOR_PRIVACY_METADATA | 6 months | YouTube sets this cookie to store the user's cookie consent state for the current domain. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| Cookie | Duur | Beschrijving |

|---|---|---|

| _cfuvid | session | Description is currently not available. |

| loglevel | never | No description available. |